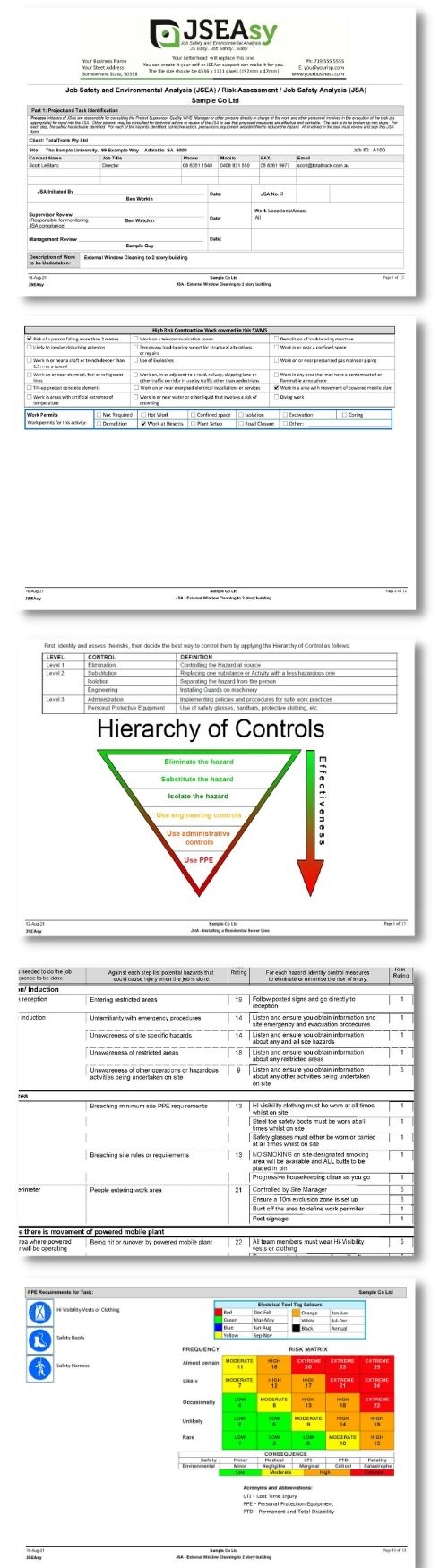

A Job Safety Analysis (JSA), is a systematic process used to identify, assess, and mitigate hazards associated with specific tasks or jobs in the workplace. The primary goal of a JSA is to prevent workplace accidents, injuries, and illnesses by proactively identifying potential hazards and implementing control measures to minimize or eliminate risks.

The process typically involves breaking down a job or task into its individual steps and analyzing each step to identify potential hazards and then ways to control them.

Its primary purpose is to help supervisors and workers implement and monitor the control measures established at the workplace to ensure high risk work is carried out safely.

The concept of a Job Safety Analysis (JSA) has its roots in the early 20th century with the emergence of industrial safety practices. While it’s challenging to pinpoint an exact date or inventor for the JSA process, its development can be traced back to the evolution of occupational safety and health practices.

During the early 20th century, industrial accidents were common, and there was a growing recognition of the need to systematically identify and control workplace hazards to prevent injuries and fatalities. As industries expanded and became more complex, there was a greater emphasis on improving workplace safety.

The JSA process likely evolved over time as a response to this need, drawing on principles from fields such as engineering, psychology, and industrial hygiene. The process involves breaking down job tasks into individual steps, identifying potential hazards associated with each step, and implementing controls to mitigate those hazards.

While there may not be a single inventor or specific date associated with the creation of the JSA process, it has become a fundamental tool in occupational safety and health management. Organizations worldwide use JSA or similar risk assessment methods to proactively identify and manage workplace hazards, demonstrating a commitment to worker safety and well-being.

Dogmen

Domestic Builders

Doors and window fitters

Drain Layers

Earth Moving

Electricians

Excavation

Fencing

Fire Protection

Footing Contractors

Form workers

Foundation Contractors

Glaziers

Gyprockers

Arboriculture

Floriculture

Landscape Horticulture

Olericulture

Oneology

Parks and Gardens

Pomology

Postharvest physiology

Turf Management

Viticulture

Aerospace manufacturing

Agribusiness

Automotive industry

Biotechnology

Brewing industry

Bus manufacturing

Chemical industry

Clothing industry

Construction

Electronics

Emerging technologies

Energy industry

Engineering

Food and Beverage

Food processing

Free machining

Industrial design

Industrial Engineering

Interchangeable parts

Machine tools

Metalcasting

Metalworking

Nanotechnology

Pharmaceutical

Plastics

Process Engineering

Production engineering

Pulp and paper industry

Sailmaker

Semiconductor

Shipbuilding

Steel production

Synthetic biology

Bioengineering

Telecommunications

Tentmaking

Textile manufacturing

Tire manufacturing

Tool and die maker

Transportation

Airline Cabin Staff

Bars

Cafes

Cleaners

Guest Services

Hostels

Hotels

Housekeeping

Kitchens

Maintenance

Motels

Nightclubs

Public houses

Reception

Restaurants

Travel agents

Air

Animal-powered

Boats

Buses

Cargo

Cars

Couriers

Ferries

Freight

Human-powered

Passenger

Rail

Road

Ships

Shipping

Taxis

Trucks

Water

Acting

Broadcasting

Comedy

Composers and songwriters

Concert hall

Discotheques

Fashion industry

Film

Film production

Film score

Film studios

Live entertainment

Modeling

Movie theaters / cinemas

Music industry

Musical theatre

New media

Orchestras

Performance art

Radio

Reality television

Singers and musicians

Sports

Television

Theme parks

Allied Health Professionals

Assisted Living

Caring

Chiropractic

Clinic

Dentistry

Healthcare Science

Hospital

Massage

Medicine

Nursing

Nursing Home

Pharmacy

Physio

Teaching Hospital

Catering

Driller

Electricians

Electronic Engineers

Environmental Science

Equipment Operator

Field Assistant

Fitting & Machining

Geological engineering

Geophysicist

Laboratory Assistant

Labourer

Mechanics (Diesel & Plant)

Metal Fabrication

Miner

Rigger

Shotfirer

Surveying

Truck Driver

© JSEAsy | Disclaimer & Privacy Policy | Website developed by Foreunner Computer Systems